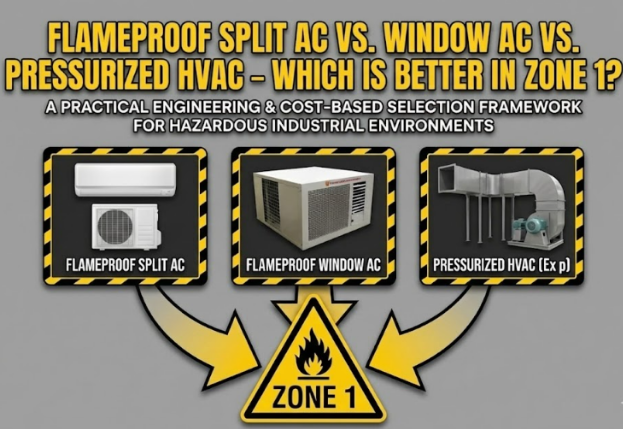

For Zone 1 hazardous environments, Flameproof Split AC is the preferred and most widely adopted solution due to better installation flexibility, lower noise, and superior reliability.

Flameproof Window AC is suitable for small enclosures and limited-size rooms in Zone 2.

For deeper context on hazardous classifications, review: A Comprehensive Guide to Zone 0, Zone 1, Zone 2 & Zone 3 – Read the Zone Classification Guide

Feature | Flameproof Split AC | Flameproof Window AC |

Typical Capacity | 1–2 TR | 1–2 TR |

Indoor Noise | Low | High |

Installation Space | Indoor + mounted condenser | Single unit |

Installation Complexity | Medium | Simple |

Best Use Case | Zone 1 rooms, MCC areas | Small Zone 2 rooms |

Maintenance | Easy indoor access | Difficult |

PESO Compliance Acceptance | Strong | Conditional |

Cost Level | Medium | Lower |

Reliability | High | Medium |

Explore certified solution options: Flameproof Split Air Conditioner

Although flameproof window ACs were widely used historically, they present limitations:

Modern split AC systems commonly use R410A and R32 refrigerants.Since R32 is mildly flammable, having a hermetically sealed Ex d compressor in a Flameproof Split AC significantly reduces ignition risk compared to older window AC designs lacking robust containment.

Best Application | Reason |

Crane cabins | Compact installation |

Small guard/control booth | Low airflow requirement |

Temporary retrofits | Speed and cost |

Benefit | Explanation |

Low noise | Indoor fan coil unit separated from compressor |

Better service access | Compressor positioned externally for maintenance |

Flexible location | Indoor and outdoor units can be placed independently |

Improved plant audit score | Strong PESO acceptance and documentation |

If a safe (non-hazardous) area is located nearby:

If no safe zone is available:

This configuration is common in:

Zone | Recommended System | Reason |

Zone 1 | Flameproof Split AC or Pressurized HVAC | Frequent flammable gas presence |

Zone 2 | Window AC or Split AC (preferably Ex d) | Gas present only under abnormal conditions |

Zone 0 | No AC permitted | Only intrinsic safety electronics allowed |

Learn more about flameproof safety:

Situation | Recommended System |

Small room <120 sq ft | Flameproof Window AC |

Medium room 120–300 sq ft | Flameproof Split AC |

Large control room | Pressurized HVAC |

Offshore and corrosive zone | Pressurized HVAC |

Noise-sensitive operations | Split AC |

No safe outdoor area | Split AC with Ex d outdoor |

A pharmaceutical manufacturing unit in Maharashtra replaced two FLP Window ACs due to repeated breakdowns and noise interference affecting PLC monitoring.

Switching to 1.5 TR Flameproof Split AC installed with outdoor unit in Safe Zone achieved:

Can I use a standard split AC with explosion-proof add-ons?

No. Retrofitted or sensor conversions are not certified and violate PESO guidance.

Can a window AC be used in Zone 1?

Not recommended. Only in Zone 2 if certified.

Do flameproof split ACs require special cabling?

Yes. Must use armored cables with Ex d glands and certified sealing systems.

Choosing the correct HVAC system for hazardous industrial environments is a high-impact engineering decision.

For most Zone 1 facilities, Flameproof Split AC delivers the best combination of safety, flexibility, efficiency, and compliance.

Window AC serves limited small-room use cases in Zone 2, while Pressurized HVAC is unmatched for large or mission-critical environments.

Explore industrial-grade HVAC solutions built for hazardous applications: Flameproof Split Air Conditioner — Explore Solutions