Zone 0 is the highest explosion-risk classification within hazardous area engineering. It represents a location where flammable gas, vapour, or mist is present continuously, for long durations, or frequently during normal operations. Because an explosive atmosphere is assumed to exist at all times, installation regulations for Zone 0 are exceptionally strict, and even a minor mistake can trigger ignition.

Typical Zone 0 environments include:

To understand Zone classifications, refer to: A Comprehensive Guide to Zone 0, Zone 1, Zone 2 & Zone 3 – Read here

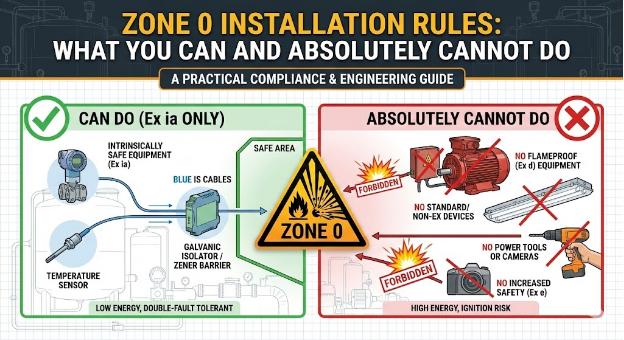

Only intrinsically safe equipment certified Ex ia (or Ex ma / Ex s under specific cases) is permitted inside Zone 0. Flameproof (Ex d), Increased Safety (Ex e), or any standard powered electrical equipment is strictly prohibited. The Intrinsically Safe Barrier must always be located in the Safe Area or in a Zone 1/Zone 2 certified panel — never inside Zone 0.

Allowed Equipment | Protection Concept | Example Applications | Notes |

Intrinsic Safety Ex ia | Limits energy to prevent ignition | Pressure transmitters, ultrasonic level sensors | Mandatory protection method |

Encapsulation Ex ma | Fully resin-sealed electronics | Special analyser modules | Restricted use case |

Simple Apparatus | Passive, low-energy devices | RTDs, thermocouples, reed switches | Must still connect to IS barrier |

Certified Portable IS Devices | Safe low-energy circuits | IS portable gas detector, IS torch | Certified only |

Equipment Type | Reason for Prohibition |

Flameproof (Ex d) enclosures | Cannot contain continuous internal ignition safely |

Increased Safety (Ex e) devices | Not designed for continuous explosive atmosphere |

Normal CCTV cameras or lighting fixtures | High-temperature surfaces and spark risk |

Any motors or AC-powered devices | Excessive ignition energy |

Non-IS cabling and joints | Can carry ignition energy into zone |

Equipment Type | Allowed in Zone 0? | Allowed in Zone 1? | Typical Protection Used |

Flameproof (Ex d) hooter | Never | Yes | Ex d IIC T6 |

Flameproof camera | Never | Yes | Ex d IIC T6 + IP68 |

Flameproof Split AC | Never | Yes | Ex d |

Intrinsically safe transmitter | Yes | Yes | Ex ia IIC T6 |

Normal LED torch | Never | Never | – |

Rechargeable IS torch | Yes (certified) | Yes | Ex ia IIC T4 |

Explore intrinsically safe portable devices: Flameproof Torch Rechargeable

Flameproof Ex d equipment is engineered to contain ignition internally and prevent flame propagation externally. This protection principle relies on the assumption that gas is normally absent around the enclosure.

In Zone 0:

Therefore, Ex d is restricted to Zone 1 and Zone 2, never Zone 0.

Requirement | Correct Practice |

Intrinsic Safety Level | Ex ia only (Ex ib only Zone 1 permitted) |

Barrier Location | Barrier must be in Safe Area / Zone 2 enclosure, never Zone 0 |

Cable Colour | Blue — dedicated Intrinsically Safe cable |

Cable Segregation | 50 mm minimum separation from non-IS circuits |

Earthing | Dedicated IS reference earth |

Wire Termination | Screw-type only, no sparks permitted |

Inspection | Visual & documentation-based every 6–12 months |

A frequent mistake in field installations is positioning the IS barrier close to the sensor. This is not permitted.

Correct Rule:

The Intrinsic Safety Barrier (Galvanic Isolator or Zener Barrier) must always be installed in the Safe Area or in a certified Zone 1/Zone 2 enclosure. Only the blue intrinsically safe cable is allowed to enter Zone 0.

Incorrect installation example: Barrier mounted at vessel top → immediate ignition risk.

Correct installation example: Barrier installed in control room MCC / PLC panel → safe and compliant.

Violation | Risk |

Using Ex d junction box inside Zone 0 | Contained spark source |

Running normal cables | Brings ignition energy into zone |

Installing lamp/torch inside tank | Surface temperature hazard |

Using portable power tools inside manway | Fatal spark potential |

No segregation of IS and non-IS cable trays | Energy coupling |

Requirement |

|

|

|

|

|

In a solvent tank farm, a temporary portable inspection lamp was introduced through a manhole during maintenance. The lamp was not intrinsically safe and generated enough heat to exceed the Auto-Ignition Temperature of stored solvent vapours.

A near-miss incident led to full compliance upgrade with IS torches and properly installed galvanic isolators, enabling the plant to pass subsequent PESO inspection.

Explore certified safety products: Flameproof Torch Rechargeable

Can flameproof (Ex d) equipment ever be installed inside Zone 0?

No. Ex d is never permitted in Zone 0.

Can I install a camera inside Zone 0?

No. Use a Zone 1 flameproof camera positioned externally to view inside.

Can simple thermocouple wires be used directly?

Only when connected through a certified IS barrier.

Zone 0 demands absolute discipline, strict intrinsic safety design, correct barrier placement, and complete avoidance of Ex d or any powered equipment.

A sound Zone 0 system ensures compliance, worker safety, and operational reliability — avoiding catastrophic ignition events.

For more certified flameproof safety solutions: Explore Flameproof Products